Company of the Month: OpenCell

OpenCell was founded in June 2018 to provide early-stage biotech start-ups with affordable space in White City, London. They created a solution for biotech start-ups, who are often emerging from university and unprepared for the difficulty and logistics of running their first lab.

Over the past two years they have grown from three to 70 shipping containers with laboratories available for work on synthetic biology, CRISPR, DNA sequencing, therapeutics, biologics, hardware, biomaterials, bioplastics and more. Some of the companies on site include Aptogen Ltd, who design and produce customised molecular biology reagents; Zio Health, a biosensor platform technology; and My Personal Therapeutics, who develop AI algorithms to identify drug treatments for patients based on their tumour genetics.

COVID-19 Project

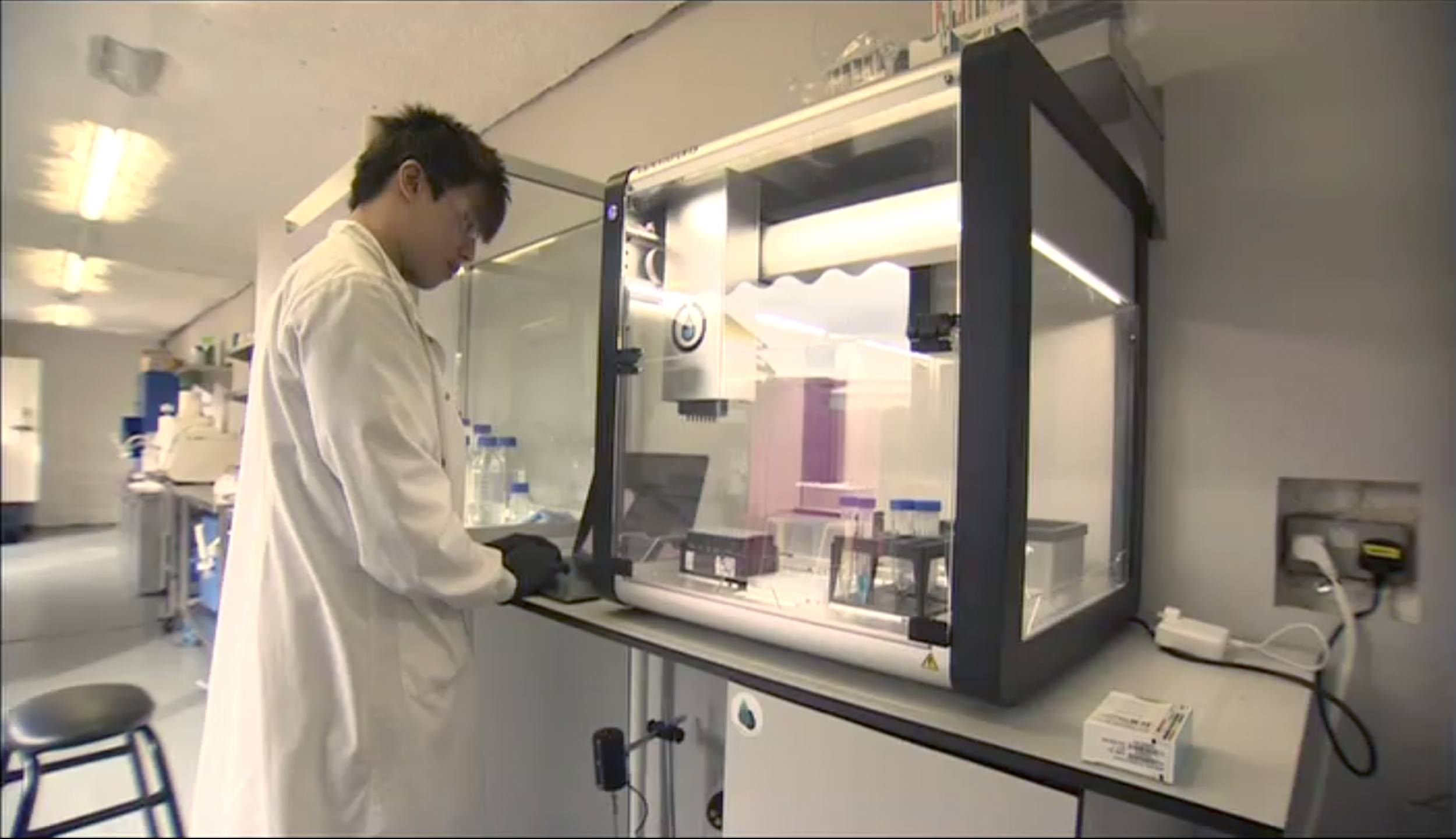

OpenCell recently hit the news with their work to fight the COVID-19 global pandemic in their open source testing facilities. They are looking to deploy a testing system that uses liquid handling robots and molecular assays in order to increase testing capacity to >10K a day in two weeks using lab automation infrastructure. At the current exponential growth rate, they believe there will be a daily increase of 1,000-10,000 infected people by the end of the month. Their plan is to act quickly to take the burden of testing off the NHS and ensure that those infected undertake appropriate isolation procedures.

Tom Meany, Co-founder at OpenCell, says that population-scale testing for COVID-19 is one of the best ways to limit mortality rates. Large-scale testing finds and isolates infections quickly, limiting the virus’ spread and protecting vulnerable populations. At present, all their testing operates out of their shipping container labs, but to scale this up in to the millions, they are looking for more space.

MedCity has endorsed OpenCell to the start-up community since its inception. They are also supporting their COVID-19 work by sourcing expansion locations for additional testing sites, helping the team to secure equipment such as real-time PCRs from industry and academia, and creating clearer communication channels with Public Health England and the Greater London Authority.

Tom Meany, Co-Founder, OpenCell, said:

“I would argue that we are the best equipped team in London to deliver modular, high throughput, automated facilities for biotechnology. Our core focus is on getting the right infrastructure, which was a problem even before the public health crisis. We have been pressing for increased research space in London for some time and it’s really disappointing and unproductive that even now, science is not getting the support it needs.”

The team has been working with US-based OpenTrons, who has donated two of their liquid handling machines, to create a scalable automated solution that can massively increase sample testing. By completing this rapid scale up the team would be capable of guiding other lab facilities on adding this capability.

Open Source working

Alongside private labs, OpenCell hosts core facilities that are shared by all including a lab store, waste management, refrigeration, microscopy and shared lab spaces for molecular biology and microbiology. The combination of privacy and community helps to encourage interactions and collaborations between groups, but provide a healthy respect of IP boundaries. The team is passionate about open source working and has a long-standing relationship with OpenTrons, because they operate in a similar manner. Their technology is open for modifying and sharing, making it easily accessible and more collaborative.

Tom said:

“OpenSource technology is a big part about what we develop here and is becoming the new norm, with the likes of Microsoft, GitHub and Red Hat working in this way. Traditionally, biotechs have been structured around a proprietary supply chain, so everything is custom-made in isolation, and top-secret. By enabling our customers to interact with the development of a product, it is more cost-effective and produces better products.”

Expanding internationally

OpenCell are open to working with NHS facilities across the country to provide their high throughput liquid handling, which could increase their efficiency x 100. If they can operate and grow this successfully, they have plans to expand globally to increase testing, encourage isolation and stop the spread of the virus. Their goal is in line with the Head of the World Health Organisation’s key message, which is to “test, test, test” with an urgent need to escalate testing, isolation and contact tracing.

Tom said:

“We’re talking to people in South Africa, Nigeria, Switzerland, and Asia, who are really keen on having a portable facility. You have seen how effective drive-through testing has been in South Korea and people want to deploy testing facilities at the side of road and have appropriately licensed personnel carrying out the tests. Frontline care is of course hugely important, and we need more beds and ventilators, but we have to test people to find out if they have it and need to self-isolate.”

How the testing works

The testing process involves a core procedure: reverse transcription polymerase chain reaction (RT-qPCR), which acts to amplify a section of DNA (or RNA) molecules in a sample to a measurable level and complete a quantitative read out optically. To perform the qPCR they need to complete a sample collection, perform preparation steps and finally undertake the measurement.

First, they swab a cheek and place it in a viral inactivation buffer.

Second, they prepare the sample for RNA extraction and this is where the two OpenTrons liquid handling units enters. The effort of doing one measurement is the same effort as doing 96.

Third, they remove the RNA from solution using magnetic beads. The RNA attaches to these beads and then they resuspend in wash buffers and finally elute.

Finally, they take the eluted RNA and prepare by mixing with the qPCR reagents and place in a compatible 96 well plate.

The qPCR can give a valid output in as little as an hour and the total process flow could take as little as five hours. The system will complete 400-500 runs in a day if operated at maximum load. By optimally configuring layout and adding additional robotic units they could scale to >10K runs/day by replicating the system 20 times.

This is a technically challenging project requiring substantial support in the lab, both locally and with remote expert guidance. We may additionally need to be able to deliver this system to NHS facilities using shipping container labs. We may need to advise policy makers on reducing current testing restrictions and support on this process is vital.

What they are looking for

To reach their goal of testing 10,000 samples a day they are looking for the help of a wide range of specialists and passionate people to help on the challenges, which relate to:

- OpenTrons programming

- OpenTrons tools and add on expertise

- Reagent suppliers

- Appropriate experimental controls

- qPCR and rtqPCR experience

- Molecular protocol design

- RNA expertise

- Data Science and Bioinformatics

- Privacy (Data)

- Regulatory expertise

- Patient Sampling

- Patient support

Tom said:

“Those who can help with qPCR are top of the list but we’re also looking at lab consumables and reagents – it’s all hugely advantageous. We will also have a lot of data and need help managing, securing, maintaining and mining that data. But infrastructure is the real problem that is not going away. What people can forget is that biotech is healthcare and when we see an outbreak like this, we really need additional equipment which is locked away in research centres and universities. We all need to come together – councils, government, universities, and industry – to acknowledge that this is an emergency situation and that we need to share our assets and expertise.”