Meet the Future of Green Healthcare

Last week we launched Unleashing Innovation 2021, our report showcasing innovations in the London ecosystem that are moving the healthcare sector toward a greener future. The founders of these new enterprises come from diverse backgrounds and disciplines, and are tackling the challenge of climate change from different angles.

The investment landscape is underlining the significance of innovators like these. PwC’s report on Climate Tech out this week reveals London as the number 2 hotspot for global Climate Tech investment, fuelling growth in climate tech investment of 200% year on year worldwide. This comes amid a warning that to avoid more than 1.5°C of warming, the world now has to decarbonise at 12.9% a year, over eight times the rate historically achieved since 2000.

At MedCity we are making it a priority to support life sciences companies delivering carbon-zero healthcare, and to put carbon-zero strategies in place. This has never been more important – not only to tackle climate change and meet changing regulations around ESG reporting, but because investors are increasingly scrutinising the environmental impact of their targets. With that in mind, we spoke with four London founders who are showing how the healthcare sector can lead the charge in the green industrial revolution.

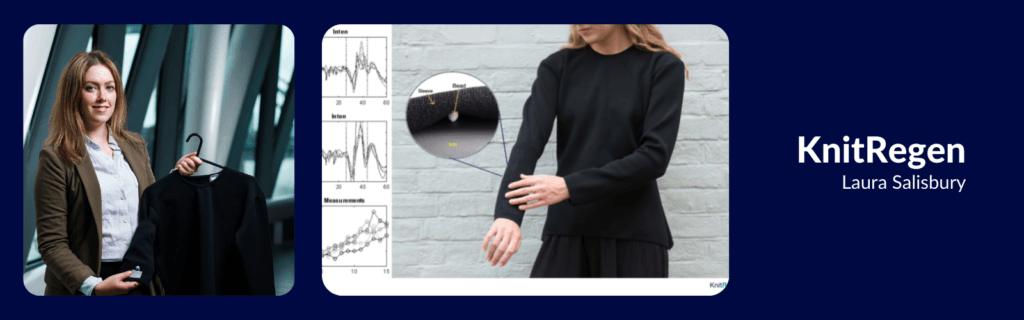

KnitRegen

KnitRegen, a start-up founded by Royal College of Art (RCA) PhD student Laura Salisbury, recently won the Mayor’s Entrepreneur Programme award in the health category.

Q: What is the idea behind KnitRegen?

Laura: KnitRegen is a wearable medtech company, creating smart garments and technology for neurological recovery. Specifically, our patent-pending smart textiles focus on enabling stroke survivors to regain lost movement by improving strength and muscle performance.

The core technology consists of a novel ‘bead’ that can be stitched into clothing, delivering timed impulses of muscle stimulation, while sensors gather data from the body to inform the level of stimulation and display the ‘recovery status’.

Q: What was your area of study prior to founding KnitRegen? And did you collaborate with others with different expertise?

Laura: I recently completed my PhD at the RCA in technical textiles for medical technologies. During this time, I collaborated with some amazing people and facilities. Namely, Professor Stuart Baker, a professor of movement neuroscience, who I’ve worked with to develop and test the technology, and Dr Rachel Stockley, who has been supporting me with advice from a physiotherapist’s perspective since 2018. I’ve also worked with material scientists and technicians at Imperial College London (Dr Peter Petrov and Dr Andrey Berevenov) and at the UK Atomic Energy Authority (Ed Eardley) to test early textile prototypes.

Working with stroke and brain injury survivors, their carers, support workers and clinicians in the community – as I’ve done for the last 3.5 years – has also been really important to inform the work.

Q: What was the catalyst for KnitRegen?

Laura: The idea was sparked from working with stakeholders, digging into the literature on stroke, and attending key lectures at UCL’s Queen Square, where I first met Professor Baker. His work inspired me to propose an alternative way for non-invasively influencing the recovery of movement.

Q: How will KnitRegen contribute to more environmentally sound healthcare?

Laura: Whilst KnitRegen’s main contribution is towards the social sustainability aspect of improving people’s lives, we are conscious of our choice of materials and the impact this has on use, mis-use and what happens when the device is ‘disposed of’.

At the moment, we’re using biodegradable materials to construct our garments and are investigating the use of energy recovery systems for powering the device.

Q: What stage are you at now? And what are your future plans?

Laura: We’ve tested our technology in a small group of ‘healthy’ participants and have demonstrated that we’re able to elicit a muscle response in everyone tested to date. That’s promising because, with the method we’re using, it’s theoretically more difficult to elicit a response in ‘healthy’ participants than stroke survivors. We’re working with the MHRA to move onto testing in stroke survivors in 2022.

Future plans include further optimisation of the bead and working with stakeholders to inform the styles of garments we look to offer.

Lixea

Lixea is an Imperial College spin-out company founded by Dr Florence Gschwend, Dr Agi Brandt and Prof Jason Hallett. We spoke to Florence Gschwend, who is now also CTO of the company.

Q. Can you tell us about your area of study and the expertise of you and your co-founders?

Florence: We’re all either chemists, with a bit of experience in chemical engineering, or chemical engineers who have worked in chemistry. Agi is still a full-time academic at Imperial College in the Chemistry Department, and Jason is a Professor of Chemical Engineering.

Q. What was the catalyst for forming Lixea?

Florence: When I started my PhD in Chemical Engineering at Imperial, Jason and Agi had been working on the idea for a while and had filed two patent applications already. As part of my PhD I also had exposure to some entrepreneurship programmes and that led me to approaching Jason and Agi to see if there was scope for us to develop a business together. We incorporated the company 4.5 years ago.

Q. What’s the idea behind the technology?

Florence: We’re using a new type of environmentally-friendly solvent called an ionic liquid – basically a salt that is liquid at room temperature. We use it to separate the different components of waste wood. The most well-known is cellulose, which has a huge array of uses, for example to make paper, textiles, and various hygiene products. Another component is lignin, which can be used to make adhesives. These components can then be turned into, for example, biofuels or new materials, replacing commonly used oil-derived materials. In a healthcare setting, this could be packaging or absorbent materials typically made from plastics. Or it could be composite materials replacing things that would be made out of steel now, like furniture or computer parts. Our process will hopefully reduce costs and make these materials available to be used in new applications where it’s currently too expensive to be used.

Q: Can you tell us about the pilot plant you’ve just set up in Sweden?

Florence: In Sweden around 75% of the country is forest. There’s a huge ecosystem around it, with the paper and pulp industry, furniture industry, and all the side streams of these.

We’re engaging with partners that can turn our cellulose and lignin into final products such as furniture.

Q. How much of an impact has being in London, at Imperial, had on the company’s foundations?

Florence: It all came out of our research at Imperial College, without that, this wouldn’t have happened. Now we rent space at Imperial, as well as having our own lab in Sweden. While the growth is happening in Sweden, we still plan to keep a presence in the lab in London because nothing compares to everything that’s available to us at Imperial College. Having access to the equipment there is very valuable to us as a start-up.

Lab Efficiency Assessment Framework (LEAF)

Developed by Sustainable UCL, LEAF is an online tool that hopes to encourage sustainability in lab research. We spoke to Martin Farley, who has led the development.

Q. Can you tell us about LEAF and its origins?

Martin: In the UK there are frameworks for labs to self-assess against in areas like health and safety. But there wasn’t something similar for sustainability. We wanted to provide standards for busy scientists, so they know exactly what actions they can take to reduce waste and the associated environmental impacts.

After piloting for a few years, we’ve now launched it as an online tool, where researchers can access a set of criteria, calculators, and a management tool. It’s focused on the lab user and everyday actions they can take, and labs are awarded a Gold, Silver or Bronze level depending on how many actions they take. The labs can then use this to showcase their credentials around sustainability, which is, I believe, something funders will increasingly be looking for.

Q. Can you tell us about your academic background and how that led you to develop LEAF?

Martin: I did an MSc in Biology at the University of Leiden in the Netherlands, where I also worked as a lab researcher. And I also worked as a technician in the US for a while at Penn State. I then did an internship at the University of Edinburgh, where we created the first post in Europe around sustainable green labs. This went quite well and I then moved to King’s College London and started a sustainable labs programme there. All of this experience helped me in developing LEAF.

Q. Did you collaborate with others to develop the tool?

Martin: I need to credit a lot of people for their support and involvement. The online tool itself has been developed by developers in the UCL Information Services Department. Designing the content of the tool was an iterative process that relied heavily on engagement with lab users and others that work in sustainability, especially Sustainable UCL and LEAN. That engagement process isn’t complete, and we continue to improve the guidance, tips and advice, hopefully setting the bar higher for users to achieve the ‘Gold’ level.

Q. Do you have specific examples of how the programme can help save resources?

Martin: One example looks at how a lab tracks what it keeps in cold storage. An ultra-low temperature freezer uses about as much energy as a house, and there is an understandable tendency to keep storing samples ‘just in case’. At the Bronze level, we simply ask labs to introduce an exit policy, that tracks the materials of departing staff and scientist. As you move through to Gold level, this progresses to logging every item in storage. It tries to take users on a journey which hopefully helps get to a point where they’re only keeping what they need (and thus using less energy on storage).

Another set of criteria we have is on research quality, which recognises that reproducibility is a factor in sustainability. Better quality data means that we get more out of the resources that we invest in research. This has been supported by the UK reproducibility network.

Q. Are you working with commercial as well as academic and institutional labs?

Martin: Since we launched the online tool in February 2021, we’ve been focused on academic labs and research institutions. The uptake in that group alone has been great – we’ve had 53 institutions, from 10 different countries sign up – but we’re looking now to make it available to industry partners in 2022.

Q. Are there any other developments on the horizon?

Martin: We’re working on developing some specialist versions of LEAF, which we plan to launch in the coming months. We’re also running a pilot with the National Technician Development Centre, recognising that technicians are often at the forefront of managing lab spaces and ensuring that they are environmentally sustainable. And we’re also running a pilot with a set of institutions in the Netherlands, where there is a great group of green labs, and some exciting things happening.

Cryogenx

Cryogenx are developing radical new medtech devices to enable people to perform in high heats. We spoke to Founder and CEO Matt Anderson.

Q. Can you tell us about your academic background and how it led to Cryogenx?

Matt: I studied industrial design technology at Brunel University. My final project was a very broad ‘solve a problem’. I ended up looking into heatstroke and how underrepresented it is, both in terms of people’s awareness, and in innovation. I discovered there was no real viable solution available for treatment, aside from a full body ice bath, and developed the fundamental concept of a portable, wearable high performance body cooling device. Since leaving university, I joined the Central Research Laboratory Accelerator and received funding. I’ve armed myself with a team of very skilled engineers, who have been able to refine and develop the thermal and fluid dynamics in the system, to bring it to market.

Q. How big an issue is heatstroke?

Matt: Globally, around 490,000 people die every year from heat exposure or heat stress and this is going to grow exponentially with climate change. There’s very little awareness about how it manifests and the impact it has, but by 2030, the UN predicts that heat stress will cost the global economy $2.4 trillion a year in lost work and health care bills. We need to be able to cater to live in a hotter world but we don’t currently have a solution for heatstroke. We hope to deliver that.

Q: What stage are you at with launching the product?

Matt: We’re currently nine months through an 18-month product development cycle, working towards having a full-scale testable device to take to preclinical research trials in Q3 2022. We see our technology being deployed within any industrial or public setting where heat is combined with physical exertion. Typical industries would be construction, sports, defence, public health… There are also certain parts of the world, particularly the Middle East, parts of America and southern Europe, where temperatures frequently breach 40-45 degrees. Humans cannot survive without cooling in those temperatures, so there is a wider demand from the general public that will lead to a need for personal cooling devices in order to live in hotter climates.

Q: And how does your solution compare to current methods, resource-wise?

Matt: A full body ice bath typically uses 200 litres of water, and relies on onerous methods and resource use. Our solution emulates ice water immersion via a thermal membrane in a lightweight pad fitted directly to the torso. This uses less than 2% of resources comparatively, and it doesn’t rely on any special storage or logistics. It can be operated by any person in any scenario.

The core cooling elements of the device are also reusable, further enhancing sustainability, although, due to medical regulations, any surface that comes into contact with a patient needs to be disposable.

Q. In the future, how widely accessible do you see this device becoming?

Matt: We see this potentially being similar to the current situation with defibrillators, which are widely accessible in public spaces where they are needed. In our case, that would be in climates where heatstroke is a common occurrence. There is potentially also a tangential market for sporting equipment, where it could be used as a performance enhancer, or as part of injury treatment.