Company of the Month – The Electrospinning Company

Since the formation of the Electrospinning Company as a spinout from the UK Science and Technology Facilities Council (STFC), it has established itself as a leader in biomaterial engineering. We spoke to CEO Ann Kramer about their innovations in this relatively nascent field, as well as building a gender-, age- and culturally-diverse engineering and manufacturing business.

Foundations

The Electrospinning Company was founded in 2010, with a focus on making materials for drug discovery researchers to use in the laboratory. In 2015 they saw an opportunity to use their biomaterial engineering skills to pivot the business into a new niche – making materials for medical devices. Ann explains:

The Electrospinning Company was founded in 2010, with a focus on making materials for drug discovery researchers to use in the laboratory. In 2015 they saw an opportunity to use their biomaterial engineering skills to pivot the business into a new niche – making materials for medical devices. Ann explains:

“When we looked at the opportunities where the kind of materials we could engineer would have the most benefit, moving towards medical devices was an obvious choice.”

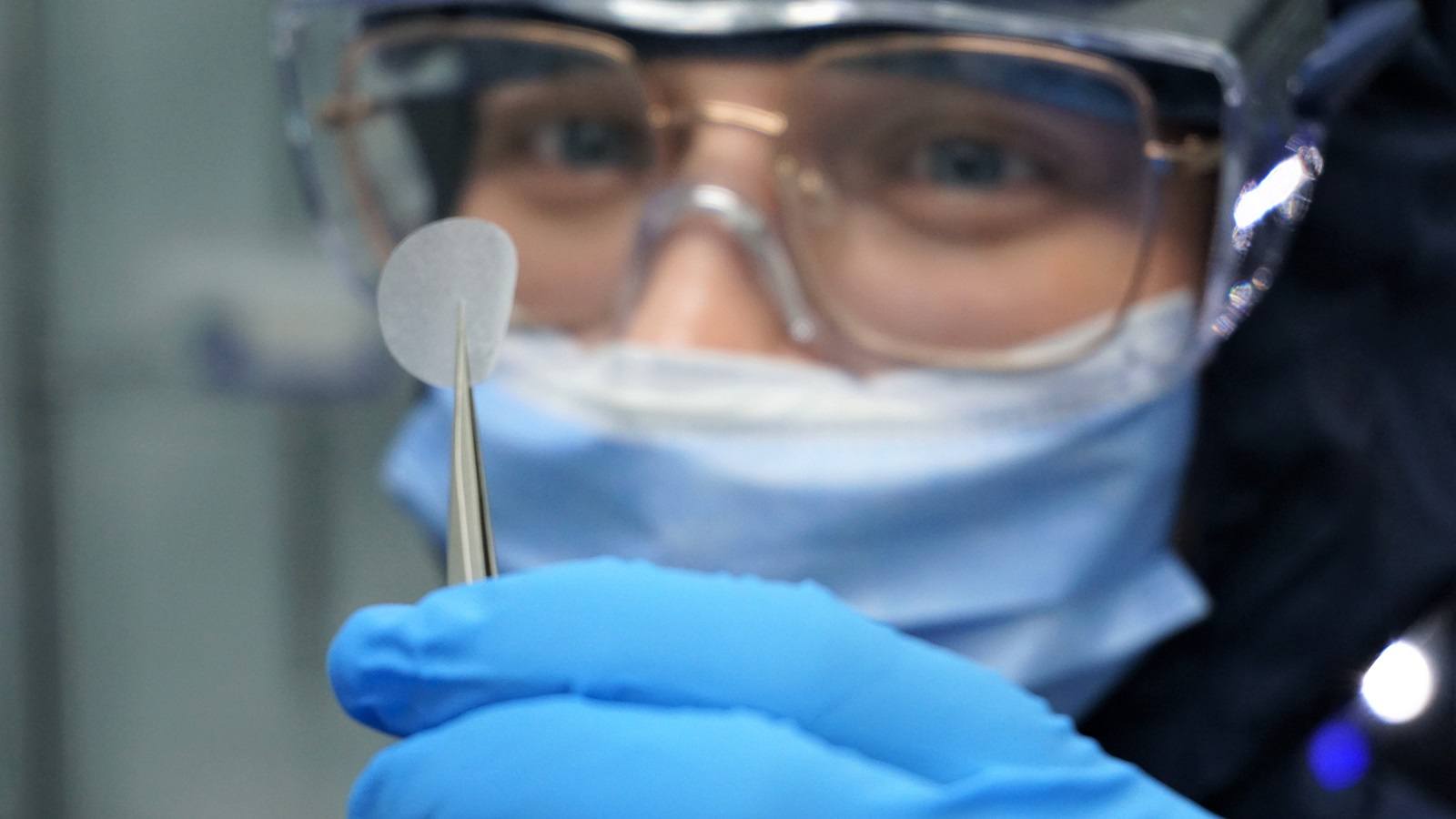

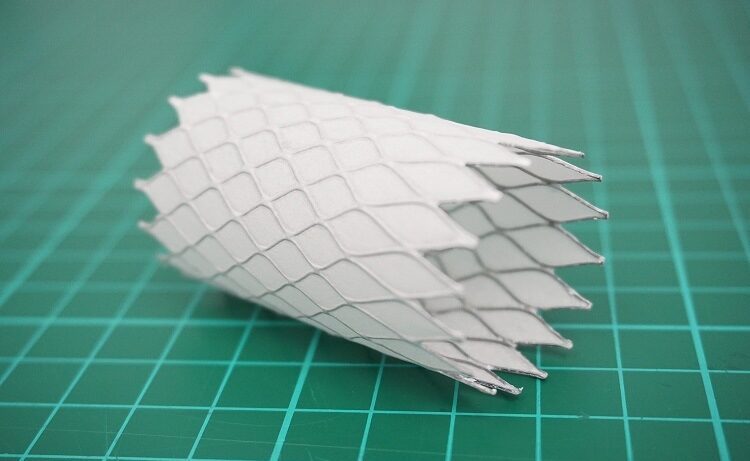

The materials Ann describes, use synthetic polymers, or sometimes biological molecules. The team’s expertise is in engineering scaffolds and membranes that resemble collagen fibres found in the body. These can then be implanted to guide natural healing in the body.

Product successes

The range of applications is broad. The company’s primary business model is as a contract design, development and manufacturing organisation, so they’ve supported the development of a wide range of products. From materials for corneal repair, to ligament wraps, they’ve worked with over 60 companies to date.

“The current ‘state of the art’ for this kind of product uses animal or human tissue. But there are issues with variability, cost and sourcing of the material, as well as ensuring that it’s been effectively treated for disease. The benefits of the synthetic materials we’re able to produce is in the availability, affordability and consistency we can achieve. The challenge, of course, is to engineer it in such a way that it’s similar enough to that natural material for the surgeon to use.”

One client they have supported through product development, clinical trials and now onto regulatory submissions in Europe and the US – Nurami Medical – have developed a graft for patients who have had brain surgery, to prevent cerebral-spinal fluid (CSF) leakage. They also make components for three sports medicine products, on the market in the US since 2016. While Ann can’t share the name of this client, she does know that over 10,000 people have been treated with these products alone.

As well as supporting clients with their product development and manufacturing, the team is also working on their own technology platform and product developments.

As well as supporting clients with their product development and manufacturing, the team is also working on their own technology platform and product developments.

They are developing the capability to spin a coating directly onto stents used in vascular surgery. They are about to enter preclinical safety testing of another product – Symatix® membrane – an innovative synthetic amniotic membrane substitute (amniotic membrane is commonly used in treating disorders and wounds in the eye). And another technology platform – Kalyptix® – is being developed to produce a microscopic protective membrane for cells in cell therapy.

Funding developments

The pivot in 2015 to medical devices came with its challenges. It required investment in quality certification and clean room facilities that would satisfy both clients and regulators. As well as grant and loan funding from Innovate UK and the EU, the company sought angel investment in 2015, with support from the MedCity Investment Hub. They returned to the Investment Hub in 2016, raising more angel investment to boost their manufacturing capabilities.

Since then, the company has gone from strength to strength. They successfully raised venture capital (VC) funding in 2018 to move from their clean rooms in an STFC Incubation Centre, into their own purpose-built facility in the Harwell Science and Innovation Campus, Oxfordshire. More recently, in 2021, the company entered a strategic partnership with US-based Confluent Medical (a partner in their stent coating project), gaining an injection of £4.5m investment.

“Our early involvement in the MedCity Investment Hub really set us on course for our investment journey. It was our first opportunity to position ourselves in front of a set of investors that were interested in medical devices and actually understood the sector and what it was that we were trying to do. That helped prepare us for our later VC and strategic investments and, of course, our base of angel investors are still very important to us.”

Growing a diverse business

As well as developing a diverse and innovative set of products and services, the Electrospinning Company has grown into a diverse team, as Ann is pleased to point out:

“We are an engineering company with a 50/50 gender balance. We are also age diverse, with employees in every decade – from their 20s to 60s – and we have employees of around 10 nationalities. It’s something we’re really proud of.”

On how they’ve achieved this rarity in the industry, Ann elaborates:

“We’re aware of gender, in particular, in our recruitment. While we don’t use it to impact shortlists, we do think carefully about how we word recruitment adverts and make sure the language we use in general is inclusive. Then, once you’ve started to create a diverse, welcoming environment, it’s almost like a virtuous circle – when people come to interview with us, they see a place they can be comfortable in.”

Having grown the team from just eight people in 2018 (when they moved into their own facility) to – currently – 25 people, it certainly seems like the company has no problems attracting talent.

As they continue to grow, Ann sees potential for adding to their manufacturing capacity, while retaining their current facility as a development hub.

“Our focus now is on growing the pipeline and looking for strategic partnerships for manufacturing and raw materials as products get into the market and need to be scaled up. We’re growing our service business, but also enhancing and adding to the proprietary services and products we can offer on top of that. Because it’s very much an emerging market, there’s still a lot of product and process development to be done, so there’s so much potential for innovation that can create new products and opportunities. It’s an exciting area to be in.”

Find out more: electrospinning.co.uk

Note: Symatix® and Kalyptix® are the registered trademarks of The Electrospinning Company LTD in the UK.